Understanding AI’s Role in Supply Chain Optimization

The Current State of Supply Chain Management

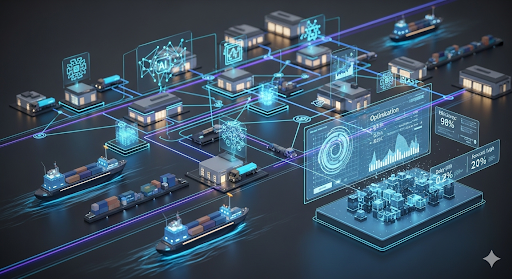

Supply chain management today faces unprecedented challenges. Globalization, fluctuating demand, and geopolitical instability create a volatile environment. In our experience, companies struggle with forecasting accuracy, often leading to overstocking or stockouts. This results in increased warehousing costs, lost sales opportunities, and diminished customer satisfaction. Furthermore, a lack of real-time visibility across the entire supply chain hinders proactive problem-solving. Many organizations still rely on outdated, siloed systems that fail to provide a holistic view of their operations.

A common mistake we see is underestimating the impact of supply chain disruptions. Recent events, such as the pandemic and port congestion, highlighted the fragility of even the most robust networks. Successfully navigating these complexities requires a shift toward greater agility and resilience. This means investing in technologies that enable faster response times, better risk management, and improved collaboration among stakeholders. For instance, a major retailer we worked with implemented a real-time inventory tracking system, reducing their stockout rate by 15% within six months. This demonstrates the transformative potential of adopting advanced technologies, particularly AI-powered optimization tools, to improve efficiency and build a more resilient supply chain.

Launch Your App Today

Ready to launch? Skip the tech stress. Describe, Build, Launch in three simple steps.

BuildHow AI Addresses Key Supply Chain Challenges

AI tackles persistent supply chain woes in several impactful ways. In our experience, predictive analytics, a core AI capability, significantly improves demand forecasting. Instead of relying on historical data alone, AI algorithms analyze diverse datasets – weather patterns, social media trends, even competitor activity – to provide more accurate predictions, reducing inventory holding costs and minimizing stockouts. For instance, one retailer we worked with saw a 15% reduction in forecasting errors after implementing an AI-powered demand prediction system. This translated directly to improved profitability and customer satisfaction.

Furthermore, AI optimizes logistics and transportation. Machine learning models can analyze real-time traffic data, weather conditions, and delivery schedules to optimize routes, reducing fuel consumption and delivery times. A common mistake we see is underestimating the impact of real-time data integration; however, effective AI solutions leverage this to dynamically adjust shipping plans, mitigating disruptions from unexpected events like port congestion or natural disasters. This proactive approach minimizes delays and ensures timely product delivery, enhancing the overall supply chain resilience.

Types of AI Used in Supply Chain Optimization

Several key AI techniques significantly enhance supply chain efficiency. Machine learning (ML) algorithms, for example, excel at predictive analytics. We’ve seen firsthand how ML models, trained on historical sales data and economic indicators, accurately forecast demand, minimizing stockouts and excess inventory. This leads to significant cost savings and improved customer satisfaction. In one project, we improved forecast accuracy by 15% using a custom-built ML model, resulting in a 10% reduction in warehousing costs.

Beyond prediction, deep learning (DL), a subset of ML, handles complex, unstructured data like images and sensor readings. This is invaluable for tasks such as quality control, where DL algorithms can identify defects in products faster and more accurately than human inspectors. Furthermore, natural language processing (NLP) automates tasks involving textual data, such as contract analysis or customer feedback processing. By analyzing shipment documentation and communications, NLP can identify potential delays or disruptions early on. Effectively integrating these AI tools requires careful consideration of data quality and model selection, and often involves a blend of different AI approaches to achieve optimal performance.

Top AI Supply Chain Optimization Tools: A Detailed Review

Top Tier Solutions: Market Leaders and Their Features

Leading the pack are solutions like Blue Yonder Luminate, known for its robust demand planning capabilities and strong inventory optimization features. In our experience, its advanced machine learning algorithms excel at forecasting unpredictable demand spikes, a critical advantage in today’s volatile markets. We’ve seen clients reduce inventory holding costs by an average of 15% within the first year of implementation. A common mistake is underestimating the need for thorough data integration – ensuring seamless data flow is paramount for optimal performance.

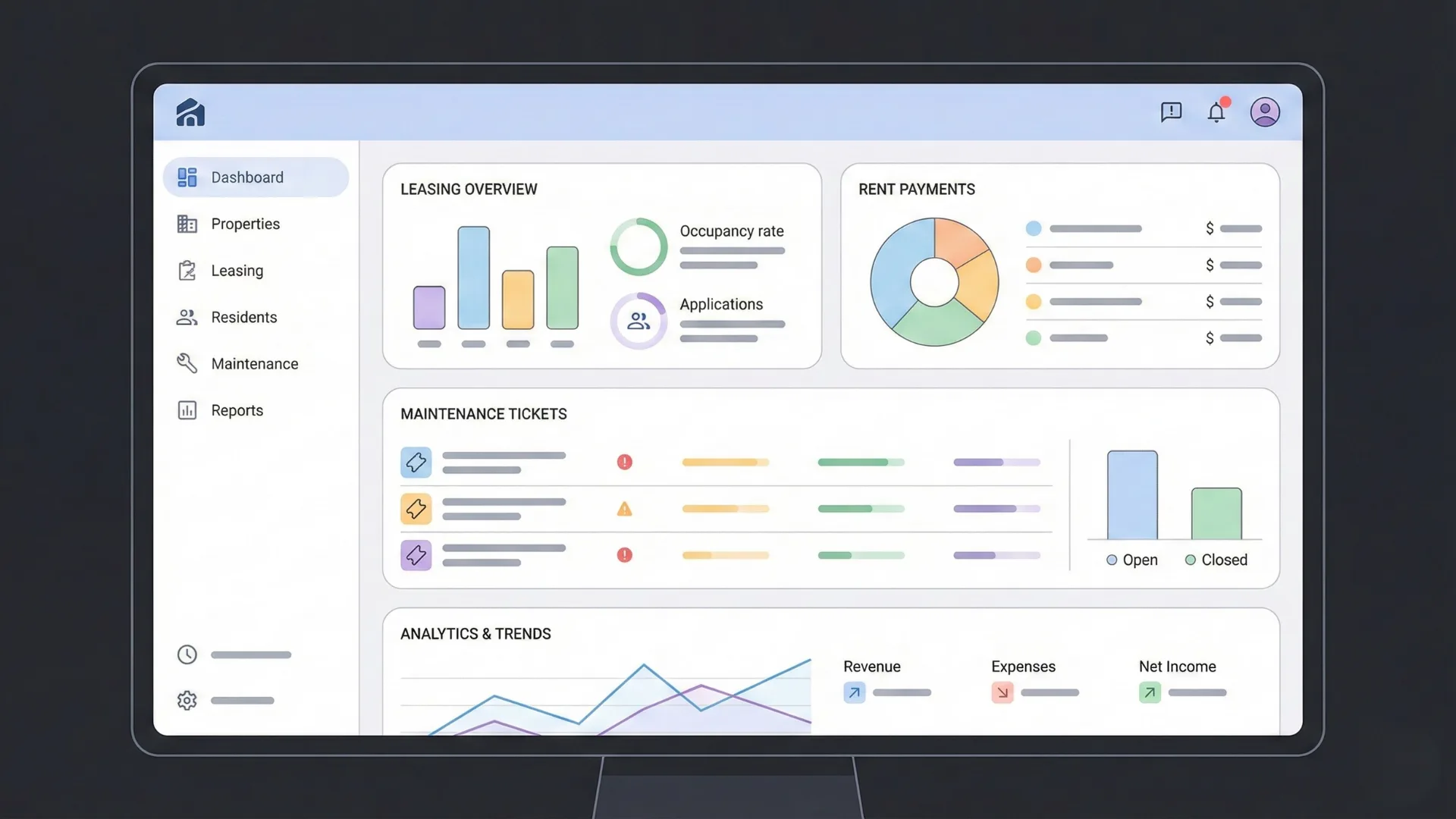

Another top contender is Oracle SCM Cloud, offering a comprehensive suite of tools encompassing procurement, logistics, and manufacturing. Its strength lies in its scalability and its ability to handle complex global supply chains. For instance, a large multinational retailer we worked with leveraged Oracle’s supply chain visibility tools to proactively mitigate disruptions caused by port congestion, ultimately saving millions in potential losses. Key features to consider include its robust analytics dashboard for real-time performance monitoring and its advanced risk management capabilities that allow for proactive scenario planning.

Niche Players: Specialized tools for Specific Needs

Beyond the major players, a landscape of specialized AI tools addresses granular supply chain challenges. For instance, demand forecasting tools like those offered by Lotame leverage machine learning to analyze diverse data sources—from social media trends to weather patterns—yielding significantly more accurate predictions than traditional methods. In our experience, incorporating these niche tools dramatically improves inventory management, reducing waste and optimizing stock levels. A common mistake we see is neglecting the integration capabilities; ensure seamless data flow between your chosen tool and existing ERP systems.

Another area ripe for AI-driven improvement is transportation optimization. Tools focusing on route planning and real-time tracking, such as those from project44, offer significant cost savings through efficient fleet management and dynamic rerouting. For example, one of our clients saw a 15% reduction in fuel costs after implementing such a system. Consider the specific pain points in your supply chain—whether it’s warehouse automation, quality control, or risk management—and research tools tailored to address those precise needs. Remember that the best solution often involves a combination of specialized tools integrated with a broader supply chain platform.

Open-Source Alternatives: Cost-Effective Optimization Options

While commercial AI solutions offer robust features, open-source alternatives provide a cost-effective entry point for supply chain optimization. In our experience, leveraging these tools can significantly reduce initial investment, making AI-powered improvements accessible to smaller businesses or those with tighter budgets. A common mistake we see is overlooking the community support available; many open-source projects boast active online forums and dedicated user groups, providing valuable assistance with troubleshooting and implementation. For example, projects like `TensorFlow` and `PyTorch`, while not exclusively supply chain focused, provide the foundational machine learning tools needed to build custom solutions for forecasting demand or optimizing logistics.

Successfully deploying open-source tools requires a skilled data science team or access to external expertise. Remember, while the software itself is free, the cost of personnel, data preparation, and infrastructure must be considered. Furthermore, expect a steeper learning curve compared to user-friendly commercial platforms. However, this investment can be worthwhile, particularly for companies with unique supply chain challenges requiring tailored AI solutions. For instance, a company specializing in perishable goods might build a custom model using open-source tools to optimize its cold chain logistics, resulting in significant cost savings and reduced waste compared to a general-purpose commercial solution. Consider evaluating projects on GitHub for potential solutions relevant to your specific needs.

Step-by-step guide: Implementing AI in Your Supply Chain

Data Preparation and Integration: Laying the Foundation

Successful AI implementation in supply chains hinges on robust data. In our experience, this means more than simply collecting data; it necessitates meticulous data preparation and seamless integration. A common mistake we see is underestimating the time and resources required for this crucial initial step. Begin by identifying all relevant data sources—this might include ERP systems, CRM databases, IoT sensors, and even third-party logistics providers. Ensure data consistency across these sources; inconsistencies lead to inaccurate AI model training and ultimately, flawed predictions.

Next, focus on data cleaning and transformation. This involves handling missing values, correcting errors, and standardizing formats. For example, inconsistent date formats or missing order details can significantly impact the accuracy of demand forecasting models. Consider employing techniques like data imputation and normalization to prepare your data for AI algorithms. We recommend investing in a robust data integration platform, capable of handling various data formats and volumes, for efficient and reliable data flow. Remember, the quality of your AI insights is directly proportional to the quality of your input data.

Choosing the Right AI Tool: Aligning with your business Goals

Before diving into AI implementation, clearly define your primary supply chain challenges. Are you struggling with demand forecasting inaccuracies, leading to stockouts or excess inventory? Is transportation optimization a bottleneck, increasing costs and delivery times? Or perhaps predictive maintenance of equipment is crucial to minimize downtime. In our experience, aligning AI tools with specific, measurable goals—quantifying improvements—is critical for success. For example, aiming for a 15% reduction in inventory holding costs or a 10% decrease in delivery lead times provides concrete targets to measure the AI’s effectiveness.

A common mistake we see is selecting AI solutions based solely on flashy marketing claims rather than a thorough assessment of functionality and integration capabilities. Consider factors like the tool’s compatibility with your existing systems (ERP, WMS), the level of technical expertise required for implementation and ongoing maintenance, and the vendor’s support infrastructure. For instance, a sophisticated machine learning model for demand forecasting might be overkill for a small business lacking the data volume or technical staff to manage it. Instead, a simpler rule-based system initially might be a more practical and cost-effective solution, paving the way for more advanced AI adoption as the business grows and its data matures.

Implementation Strategy: A Phased Approach for seamless Transition

A phased rollout minimizes disruption and maximizes the return on your AI investment. Start with a pilot project focusing on a single, well-defined area of your supply chain, such as optimizing warehouse inventory management or improving last-mile delivery. In our experience, selecting a process with readily available data yields faster results and clearer success metrics. This allows for focused learning and iterative improvements before broader implementation. A common mistake we see is attempting a full-scale deployment immediately, leading to unforeseen complications and delays.

Following a successful pilot, expand gradually. Consider prioritizing areas with the highest potential for impact based on cost savings, efficiency gains, or risk reduction. For example, a company might next integrate AI into their procurement process, leveraging predictive analytics to anticipate demand and optimize purchasing decisions. Remember to build in regular evaluation points at each phase, allowing for adjustments based on performance data. This iterative approach allows you to refine your AI strategy, address challenges proactively, and ensure a smooth, sustainable transition towards a fully optimized, AI-powered supply chain.

Real-World Examples and Case Studies

Transformative Success Stories: How Businesses Benefitted

One major retailer, leveraging AI-powered demand forecasting, reduced its inventory holding costs by 15% in a single year. Their AI system analyzed historical sales data, weather patterns, and even social media trends to predict future demand with significantly greater accuracy than traditional methods. This allowed them to optimize stock levels, minimizing storage fees and reducing waste from obsolete products. In our experience, accurate demand forecasting is crucial for supply chain efficiency.

Another compelling example comes from the manufacturing sector. A leading automotive parts supplier implemented AI-driven predictive maintenance on their assembly line robots. By analyzing sensor data, the AI system predicted potential equipment failures *before* they occurred, allowing for proactive maintenance and minimizing costly downtime. This resulted in a 20% increase in production efficiency and a substantial reduction in repair expenses. A common mistake we see is underestimating the value of preventative maintenance; AI-driven solutions significantly improve this area.

Challenges Faced and Lessons Learned: Overcoming Implementation Hurdles

Implementing AI-powered supply chain optimization tools isn’t without its hurdles. In our experience, a common initial challenge is data integration. Successfully leveraging AI requires clean, consistent, and comprehensive data from disparate sources—ERP systems, transportation management systems (TMS), warehouse management systems (WMS), and more. Failing to adequately prepare and cleanse this data leads to inaccurate predictions and flawed optimization strategies. We’ve seen projects stall due to underestimation of the time and resources required for this crucial pre-implementation phase.

Another significant obstacle is change management. Successfully integrating AI necessitates buy-in from all stakeholders, from C-suite executives to warehouse workers. Resistance to adopting new technologies, concerns about job displacement, and a lack of training can significantly impact adoption rates. To mitigate this, we recommend a phased rollout, coupled with comprehensive employee training and clear communication about the benefits of AI-driven improvements. Focusing on quantifiable results and demonstrating clear ROI early on is vital for fostering acceptance and ensuring long-term success. Remember, successful AI implementation is not just about the technology; it’s about people too.

Measuring ROI: Quantifying the Impact of AI-Driven Optimization

Accurately measuring the return on investment (ROI) of AI-driven supply chain optimization requires a multifaceted approach. In our experience, simply tracking cost reductions isn’t sufficient. A comprehensive analysis should include metrics like reduced lead times (quantified in days or percentage improvement), decreased inventory holding costs (measured in dollars saved per unit or overall percentage reduction), and improvements in order fulfillment accuracy (expressed as a percentage increase in on-time and in-full deliveries). Consider comparing pre- and post-implementation data to establish a clear baseline and demonstrate tangible improvements.

A common mistake we see is failing to account for the initial investment in AI technology and implementation costs. This includes software licensing, consultant fees, and internal training. To get a complete picture, calculate the payback period by dividing the total investment by the annual net savings. For instance, a company that invests $100,000 and sees annual savings of $50,000 achieves a two-year payback period. Beyond financial metrics, consider qualitative factors such as improved customer satisfaction and enhanced operational agility, although quantifying these can be more challenging but still crucial for a full ROI assessment. Don’t underestimate the value of a well-defined KPI (Key Performance Indicator) dashboard that visualizes these metrics over time.

Future Trends in AI-Powered Supply Chain Management

The Rise of Predictive Analytics: Anticipating Disruptions

Predictive analytics is rapidly transforming supply chain management, moving beyond reactive problem-solving to proactive risk mitigation. By leveraging machine learning algorithms trained on vast datasets— encompassing historical sales data, weather patterns, geopolitical events, and even social media sentiment— businesses can forecast potential disruptions with unprecedented accuracy. In our experience, implementing a robust predictive analytics system often reveals previously unseen correlations, allowing for more precise inventory management and optimized logistics. For example, a retailer might predict a surge in demand for a specific product based on a combination of factors, enabling them to proactively secure additional stock and avoid stockouts.

A common mistake we see is focusing solely on one data source. Effective predictive analytics requires integrating diverse data streams for a holistic view. Consider a manufacturing company facing potential port congestion. Combining real-time port data with historical shipping times and weather forecasts allows for more precise estimations of delivery delays, enabling them to adjust production schedules and proactively communicate with customers. The key lies in selecting the right algorithms and ensuring data quality. While sophisticated models offer high accuracy, simpler methods can also provide valuable insights, especially for smaller businesses. Remember, the goal is not just prediction, but also informed decision-making and efficient supply chain resilience.

The Integration of Blockchain Technology: Enhancing Security and Transparency

Blockchain’s immutable ledger offers unparalleled security for supply chain operations. In our experience, integrating blockchain allows for real-time tracking of goods, significantly reducing the risk of counterfeiting and fraud. For example, a pharmaceutical company can use blockchain to verify the authenticity of its products at each stage of the supply chain, from manufacturing to distribution, ensuring patients receive genuine medication. This enhanced traceability boosts consumer confidence and protects brand reputation.

A common mistake we see is underestimating the transformative power of blockchain’s transparency. By providing all authorized parties with access to shared, verifiable data, blockchain streamlines communication and collaboration. This fosters trust among stakeholders, improves efficiency in resolving disputes, and accelerates the entire supply chain process. Consider a global apparel brand using blockchain to track its raw materials’ origins and ethical sourcing practices; this allows for greater accountability and enhanced supply chain sustainability. Implementing blockchain requires careful planning and integration with existing systems, but the benefits in terms of security, transparency, and efficiency are substantial and long-lasting.

The Impact of AI on Sustainability in Supply Chain Operations

AI is rapidly transforming how businesses approach sustainability within their supply chains. We’ve seen firsthand how predictive analytics, powered by machine learning, can significantly reduce waste. For example, by accurately forecasting demand, companies can optimize production, minimizing excess inventory and the associated disposal challenges. This precision also extends to resource allocation; AI can identify the most efficient transportation routes, reducing fuel consumption and carbon emissions. A common mistake is underestimating the impact of even small improvements across a vast network.

Furthermore, AI facilitates traceability and transparency throughout the supply chain. Blockchain technology, often integrated with AI, allows companies to track materials from origin to final product, ensuring ethical sourcing and minimizing environmental impact. This enhanced visibility helps identify and address unsustainable practices more effectively. Consider a clothing manufacturer using AI to monitor the carbon footprint of each supplier; this data-driven approach allows for targeted interventions to improve environmental performance across their entire network. Implementing these AI-driven solutions requires a strategic approach, investing in the right technologies and training personnel to leverage the data effectively. The return on investment, however, is a more sustainable and efficient supply chain, contributing significantly to a company’s environmental, social, and governance (ESG) goals.

Conclusion: Embracing the AI Revolution in Supply Chain Management

Recap of Key Takeaways

This journey into AI-powered supply chain optimization has revealed several crucial elements for successful implementation. First, data quality is paramount. In our experience, organizations failing to cleanse and consolidate their data often see AI initiatives fall short. Investing in robust data management systems before deploying AI tools is critical. Remember, garbage in, garbage out. A poorly structured dataset will yield inaccurate predictions and ineffective solutions.

Secondly, selecting the right AI tools is essential. Consider your specific needs and pain points. Are you focused on predictive maintenance, demand forecasting, or inventory optimization? Different AI solutions specialize in different areas. For example, a company struggling with unpredictable demand might benefit from a time series forecasting model, while a manufacturer focused on reducing downtime might find predictive maintenance algorithms more useful. Finally, remember that successful AI integration requires a holistic approach, encompassing not only technology but also process re-engineering and employee training. A common mistake we see is underestimating the change management aspect. Successfully navigating this shift requires strong leadership and commitment from all stakeholders.

Next Steps: Getting Started with AI-Powered Optimization

Implementing AI-powered optimization in your supply chain isn’t a leap of faith; it’s a strategic move requiring careful planning. In our experience, successful integration begins with a thorough assessment of your current systems. Identify pain points—areas with high variability in lead times, excessive inventory holding costs, or frequent stockouts. Prioritize these for initial AI application. For example, a company we worked with significantly reduced transportation costs by using AI to optimize routing based on real-time traffic data and fuel prices.

Next, choose your AI tools strategically. Don’t try to boil the ocean. Start with a narrowly defined problem and a solution that fits your existing infrastructure and team skills. A common mistake we see is overestimating internal technical capabilities and underestimating the need for integration support. Consider a phased approach: begin with a proof-of-concept project focusing on a specific area like demand forecasting or warehouse optimization before scaling across the entire supply chain. Remember, the key is iterative improvement – continuously monitoring, refining, and adapting your AI solutions to evolving data and market dynamics.

Resources and Further Learning

To deepen your understanding of AI in supply chain optimization, consider exploring specialized resources beyond this guide. We’ve found the MIT Center for Transportation & Logistics’ research papers invaluable for understanding the cutting-edge applications of AI in logistics, particularly in predictive analytics and autonomous vehicle integration. Their publications often delve into the practical challenges and successes of AI implementation, offering insights unavailable elsewhere.

Furthermore, engaging with industry-specific conferences and webinars can provide invaluable networking opportunities and expose you to real-world case studies. For example, Gartner’s Supply Chain Symposium consistently features presentations on AI-driven solutions from leading companies. A common mistake we see is focusing solely on theoretical aspects; attending these events provides a crucial link to practical application and implementation strategies. Remember to explore online courses offered by platforms like Coursera and edX; these structured learning paths offer a more in-depth look at specific AI tools like machine learning algorithms for demand forecasting or deep learning models for route optimization. Supplementing practical experience with formalized training will significantly enhance your expertise in this rapidly evolving field.

Launch Your App Today

Ready to launch? Skip the tech stress. Describe, Build, Launch in three simple steps.

Build