Overview/TL;DR

- The recent Coca-Cola recall, involving foreign objects in beverages, underscores persistent vulnerabilities in even highly automated supply chains.

- Traditional quality control methods often struggle with human oversight, data silos, and an inability to detect subtle anomalies in real-time.

- AI, machine learning, and IoT offer powerful solutions through computer vision, predictive analytics, and real-time sensor data for proactive defect detection.

- SaaS founders and tech innovators have significant opportunities to develop AI-powered dashboards, edge computing solutions, and transparent monitoring tools.

- The future of manufacturing lies in self-healing supply chains and autonomous quality systems, making AI essential for preventing costly and reputation-damaging incidents.

The global supply chain, a marvel of modern logistics and automation, is often perceived as an impenetrable fortress of efficiency. Yet, even the most established giants occasionally face a stark reminder of its fragility. The recent Coca-Cola recall, a significant event that saw a major beverage producer pull products from shelves due to quality control issues, serves as a potent wake-up call. For those in tech, SaaS, and digital transformation, this isn’t just news; it’s a critical case study illuminating the gaps in current automation and the urgent need for more sophisticated, AI-driven quality control systems.

At imagine.bo, we believe these incidents are not just crises but catalysts for innovation. They highlight that while automation has streamlined production, the human element and legacy systems still introduce vulnerabilities that AI is uniquely positioned to address. This article delves into the Coca-Cola recall, explores why quality failures persist, and, more importantly, outlines how AI, machine learning, and IoT can forge a smarter, more resilient future for manufacturing and supply chains.

Launch Your App Today

Ready to launch? Skip the tech stress. Describe, Build, Launch in three simple steps.

Build

What Happened in the Coca-Cola Recall?

In a series of incidents, Coca-Cola faced recalls related to foreign objects found in its beverages. While specific details can vary by region and product line, the core issue typically involves manufacturing contaminants such as metal fragments, glass shards, or other extraneous materials making their way into sealed products. These aren’t minor hiccups; they represent a fundamental breach of quality assurance protocols and consumer trust.

The scale of such issues can range from localized batches to widespread product withdrawals, impacting millions of units and incurring substantial financial and reputational costs. The immediate public response is often one of concern and distrust, amplified by social media. For the business, the ripple effects include production halts, investigations, logistical nightmares of retrieving recalled products, and a significant blow to brand equity.

This kind of event, despite Coca-Cola’s sophisticated operations, underscores that even with extensive automation, perfect quality control remains an elusive goal. It’s a stark reminder that traditional systems, even when robust, can miss critical anomalies, paving the way for advanced solutions.

Why Quality Control Still Fails – Even in the Age of Automation

In an era where factories boast robotic arms and interconnected systems, the persistence of quality control failures in large corporations like Coca-Cola might seem counterintuitive. However, several factors contribute to these breakdowns:

- Human Oversight and Error: While automation reduces manual labor, human operators are still crucial for supervision, maintenance, and decision-making. Fatigue, distraction, or inadequate training can lead to missed inspections, incorrect machine settings, or delayed responses to alerts.

- Data Gaps and Silos: Many manufacturing environments, despite their technological advancements, still suffer from fragmented data. Sensor data might exist in one system, visual inspection logs in another, and maintenance records in a third. This siloed approach makes it difficult to get a holistic view of the production line, hindering the identification of subtle patterns that precede a failure.

- Unmonitored Parameters: Modern production lines involve countless variables. It’s economically and practically impossible to monitor every single parameter with traditional sensors and human checks. Some critical, yet overlooked, variables might be the root cause of quality issues, remaining undetected until a full-blown recall.

- Overreliance on Outdated Systems: Large corporations often operate with legacy infrastructure. Integrating new technologies with these older systems can be complex and costly, leading to a patchwork of technologies where critical data flows are not optimized or even possible. This can result in an inability to scale existing AI workflow automation tools effectively across the entire production process.

- Reactive vs. Proactive: Many quality control systems are inherently reactive. They identify defects *after* they have occurred, often at the end of the production line, or worse, after the product has reached the consumer. This approach is costly and damaging, rather than preventive.

The challenge isn’t a lack of effort but a limitation in traditional methodologies. The sheer volume and velocity of data in modern manufacturing demand an intelligence layer that human eyes and conventional software simply cannot provide.

The Role of AI and Machine Learning in Modern Quality Control

This is where AI and Machine Learning (ML) step in, transforming quality control from a reactive bottleneck into a proactive, predictive powerhouse. By leveraging advanced algorithms and interconnected systems, AI can detect anomalies with unprecedented accuracy and speed.

How Computer Vision, IoT Sensors, and Real-time Analytics Detect Irregularities

- Computer Vision: Imagine cameras constantly scanning every product on a conveyor belt, not just for obvious defects but for microscopic imperfections, color variations, or foreign objects. AI-powered computer vision systems can perform these inspections faster and more consistently than human eyes. They can be trained on millions of images to identify specific types of defects, ensuring that even the smallest anomaly, like a tiny crack or a misplaced label, is flagged immediately. This technology is already revolutionizing areas like building computer vision applications for various industrial uses.

- IoT Sensors: The Internet of Things (IoT) provides the eyes and ears of an AI-driven quality system. Sensors embedded throughout the production line can monitor a vast array of parameters: temperature, pressure, vibration, humidity, chemical composition, and even sound. When combined with AI, these sensors can detect subtle deviations that indicate a machine malfunction or a process drift long before it impacts product quality. For example, a slight increase in machine vibration might signal an impending mechanical failure, allowing for predictive maintenance. This synergy between IoT and AI is critical for smart manufacturing, as explored in articles like Combining IoT and AI in No-Code.

- Real-time Analytics: The true power of AI lies in its ability to process and analyze vast streams of data in real-time. Machine learning algorithms can identify complex correlations and patterns across disparate data points from computer vision, IoT sensors, and other operational systems. This allows for immediate detection of anomalies, root cause analysis, and even autonomous adjustments to production parameters to prevent defects from occurring. For instance, if a specific batch of raw material consistently leads to a certain type of defect, the AI can flag this material for further inspection or recommend alternative suppliers.

Case Studies or Examples of Successful AI Implementations in Manufacturing

While specific Coca-Cola recall AI solutions are still evolving, many industries have already embraced AI for quality control:

- Automotive Industry: Manufacturers use AI-powered computer vision to inspect welds, paint finishes, and component assembly with micron-level precision, catching defects that human inspectors might miss. This has drastically reduced recall rates for critical parts.

- Electronics Manufacturing: AI algorithms analyze data from hundreds of sensors on circuit board assembly lines to predict and prevent soldering defects, ensuring higher yields and reliability for devices.

- Food Processing: Beyond beverages, AI systems use hyperspectral imaging to detect contaminants, ripeness, and spoilage in fruits, vegetables, and meats, ensuring food safety and reducing waste.

- Pharmaceuticals: AI assists in drug discovery and quality control by analyzing microscopic images of compounds and monitoring environmental conditions in sterile manufacturing facilities to prevent contamination.

These examples demonstrate that AI is not just a futuristic concept but a proven solution that can significantly enhance quality control, minimize waste, and protect brand reputation.

Lessons for Tech Founders and SaaS Innovators

The Coca-Cola recall, and the broader challenges in manufacturing quality control, present immense opportunities for tech founders and SaaS innovators. The market is ripe for solutions that bridge the gap between existing automation and truly intelligent, self-optimizing production lines.

How Startups Can Build Predictive Systems to Detect Anomalies Early

- Focus on Niche Problems: Instead of trying to solve everything, identify specific, high-impact quality control pain points within an industry. For example, develop an AI solution specifically for detecting micro-fractures in glass bottles or foreign objects in liquid streams.

- Leverage No-Code/Low-Code AI Platforms: Founders don’t need extensive data science teams to get started. No-code AI platforms allow for rapid prototyping and deployment of ML models. This approach empowers predictive analytics without coding, accelerating time to market for innovative solutions.

- Emphasize Data Integration and Harmonization: Many companies struggle with disparate data sources. A SaaS offering that excels at integrating data from various sensors, legacy systems, and databases, then normalizes it for AI analysis, will be invaluable.

- Develop Explainable AI (XAI): Manufacturers need to understand *why* an AI flagged an anomaly. XAI models provide transparency, building trust and facilitating adoption. This is crucial for human operators to learn from and effectively collaborate with AI systems.

- Offer Edge Computing Solutions: Processing all sensor data in the cloud can introduce latency. Solutions that perform real-time AI analysis directly on the factory floor (edge computing) are critical for immediate anomaly detection and response.

Opportunities for Innovation: AI Dashboards, Edge Computing, Transparency Tools

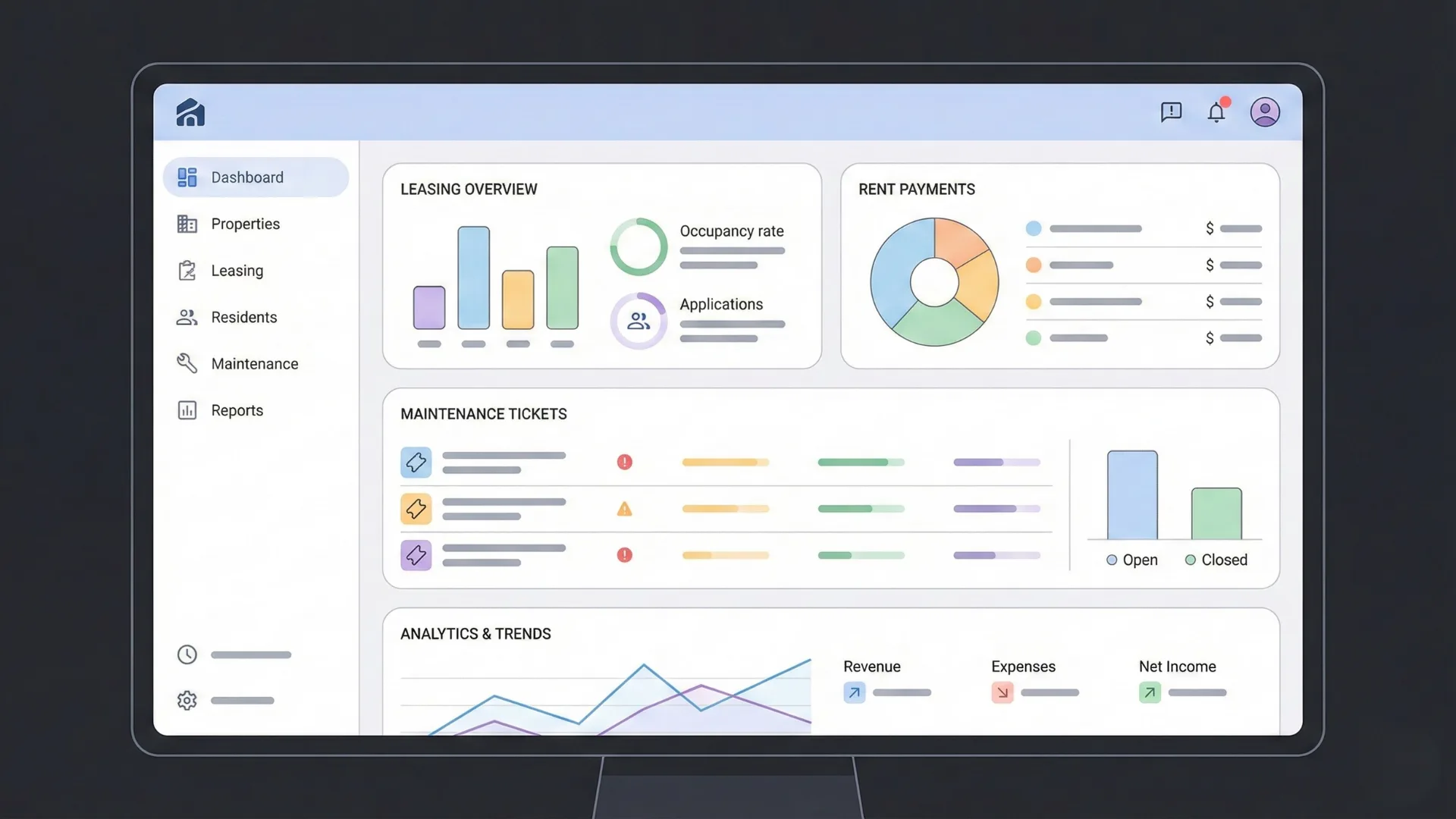

- AI Dashboards for Real-time Monitoring: Develop intuitive dashboards that provide a comprehensive, real-time view of quality metrics across the entire production line. These dashboards should not just display data but offer actionable insights, trend analysis, and predictive alerts. Imagine a dashboard that highlights ‘hot spots’ on the production line where quality issues are most likely to occur in the next hour.

- Modular AI Agents: Create specialized AI agents that can be easily deployed for specific tasks, such as visual inspection, sound anomaly detection, or predictive maintenance for individual machines. These agents can communicate with each other, forming a distributed intelligent network.

- Digital Twins for Simulation and Optimization: Build digital twins of production lines or entire factories. These virtual replicas, fed with real-time data, allow manufacturers to simulate changes, test new processes, and predict outcomes without disrupting physical operations. This enables proactive optimization and risk assessment.

- AI-powered Root Cause Analysis Tools: When a defect does occur, an AI system can rapidly analyze all relevant data points (machine logs, sensor data, environmental conditions, raw material batches) to pinpoint the exact root cause, dramatically reducing investigation time.

- Automated Compliance and Reporting: AI can automate the generation of compliance reports and audit trails, ensuring that all quality control processes meet regulatory standards and simplifying the burden of documentation.

- Transparency and Trust Tools: Given the ethical considerations surrounding AI, tools that verify data integrity, explain AI decision-making, and provide clear audit trails will be essential for adoption. This aligns with the growing importance of ethical AI in no-code development and beyond.

A Smarter Future: Preventing the Next Recall

The lessons from the Coca-Cola recall extend far beyond the beverage industry. They serve as a powerful reminder that in our increasingly complex and interconnected world, traditional quality control is no longer sufficient. The future of manufacturing and supply chain management is undeniably smart, driven by AI.

Ethical Considerations (Balancing Automation with Accountability)

As we move towards more autonomous systems, ethical considerations become paramount. While AI can significantly reduce human error, it also introduces new challenges:

- Bias in Data: If AI models are trained on biased data, they can perpetuate or even amplify existing inequalities or blind spots in quality detection. Ensuring diverse and representative datasets is crucial.

- Accountability: When an AI system makes a decision that leads to a quality failure, who is ultimately responsible? Clear frameworks for accountability, combining human oversight with AI decision-making, need to be established.

- Job Displacement and Reskilling: The increasing automation of inspection tasks will inevitably impact human roles. Companies must invest in reskilling programs to transition workers into new roles focused on AI supervision, maintenance, and data analysis.

Balancing the immense benefits of AI with these ethical considerations requires thoughtful design, robust testing, and continuous monitoring.

Future Trends: Self-Healing Supply Chains, Autonomous Monitoring, Digital Twins

- Self-Healing Supply Chains: Imagine a supply chain where AI systems not only detect anomalies but also automatically initiate corrective actions. If a machine malfunctions, the AI reroutes production to an alternative line, orders replacement parts, and schedules maintenance, all without human intervention. This concept of AI supply chain optimization is already taking shape.

- Autonomous Monitoring and Decision-Making: AI will evolve beyond mere anomaly detection to autonomous decision-making. This means systems that can dynamically adjust manufacturing parameters, optimize resource allocation, and even halt production if quality thresholds are breached, all based on real-time data and predictive models.

- Hyper-Personalized Manufacturing: AI will enable mass customization with impeccable quality. Products can be tailored to individual consumer preferences while maintaining stringent quality standards, as AI oversees every step of the bespoke production process.

- Predictive Quality Assurance: The ultimate goal is to move from detecting defects to predicting them before they even manifest. AI models, continuously learning from vast datasets, will be able to forecast potential quality issues based on raw material properties, environmental factors, and machine performance, allowing for interventions long before a product is compromised. This is a core tenet of predictive analytics with no-code tools.

Conclusion

The Coca-Cola recall isn’t just a crisis for a single brand; it’s a profound lesson for the entire manufacturing sector. It underscores that while traditional automation has brought immense benefits, it has also revealed the limitations of systems that lack true intelligence. The future of quality control, and indeed the resilience of our global supply chains, hinges on the widespread adoption of AI, machine learning, and IoT technologies.

For SaaS founders and tech innovators, this moment represents an unparalleled opportunity. By developing intelligent, transparent, and ethical AI solutions, we can transform manufacturing, prevent future recalls, and build a world where quality is not just inspected, but inherently assured. The wake-up call has been issued; now it’s time to build the smarter systems that answer it.

Frequently Asked Questions

What was the main issue in the recent Coca-Cola recall?

The primary issue in the recent Coca-Cola recall involved the presence of foreign objects, such as metal fragments or other contaminants, found in some of its beverage products. These incidents highlighted gaps in their manufacturing quality control processes.

Why do quality control failures still occur in large, automated corporations?

Quality control failures persist due to factors like human oversight, data silos across different systems, unmonitored production parameters, and overreliance on reactive, outdated inspection methods. Even highly automated lines can miss subtle anomalies without advanced AI.

How can AI prevent future recalls like Coca-Cola’s?

AI can prevent future recalls by using computer vision for microscopic inspection, IoT sensors for real-time parameter monitoring, and machine learning for predictive anomaly detection. This proactive approach identifies issues before they escalate, ensuring consistent product quality.

What opportunities does this present for SaaS founders?

For SaaS founders, this presents opportunities to develop AI-powered dashboards, edge computing solutions for on-site data analysis, and transparency tools for explainable AI. Solutions focused on predictive maintenance and real-time anomaly detection are in high demand.

What are the ethical considerations for AI in quality control?

Ethical considerations include addressing data bias in AI models, establishing clear accountability frameworks when AI makes critical decisions, and managing potential job displacement through reskilling initiatives. Balancing automation benefits with responsible implementation is key.

Launch Your App Today

Ready to launch? Skip the tech stress. Describe, Build, Launch in three simple steps.

Build